About Us

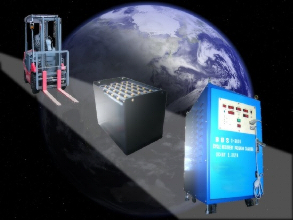

"Total Battery Maintenance Systems" is acknowledged being favorable to the earth's total environment.

"Total Battery Maintenance Systems" is acknowledged being favorable to the earth's total environment.

Ministry of Economy, Trade and Industry and Aichi Municipal Governmet gave awards to BBS for the Ecological Technology and Factory concerning battery.

The number of batteries corresponding to 40,000 folklifts are turned out every year in Japan alone. BBS is challenging to address that issue with Total Battery Maintenance Systems.

Comparing to manufacturing battery, restoreing battery uses 95% less energy. The CO2 emmision amount is also 95% less.

The core technology in Total Battery Maintenance Systems is "Multistage Multi-Loop Method Cycle Recovery Active Charger Systems".

Model A-350-12 is a handy and easy-to-use product of such technology.

Battery Technical Center, Service Factory, Headquarters and Satellite Workshop

Technical training and fundamental schooling of battery itself and on the job training of Total Battery Maintenance Systems.

The factories and workshops are equiped to diagnose, condition, restore and charger for battery users and owners nationwide.

At headquarters, we keep the database of hundres of thousands batteries' profile. That keeps us leader and innovator in battery maintenance world.

We prepare the battery diagnosis professional training institution.

Brief History

1992 Established OHK Lab to sutudy battery restoration technology

1999 Developed cycle recovery charger

2006 Awarded by Aichi municipal government

2007 Awarded by Ministry of Economy, Trade and Industry

2010 Developed Multistage Multi-Loop Method Cycle Recovery Active Chaeger

2011 Started the service of restoration of communication facility's battery

2013 Developed storage battery systems for disaster prevention

2014 Installed storage battery systems for solar power in Tokunoshima Iland

Address and Phone

1-10, Kiki-higashi, Komaki, Aichi, Japan 485-0059

Phone: +81 568 54 8021 FAX: +81 568 54 8204

CEO and Chief Technical Officer: Katsuo Okada